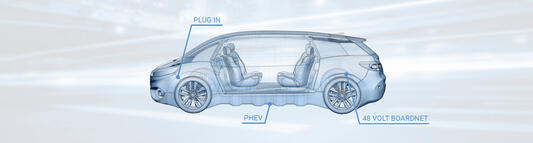

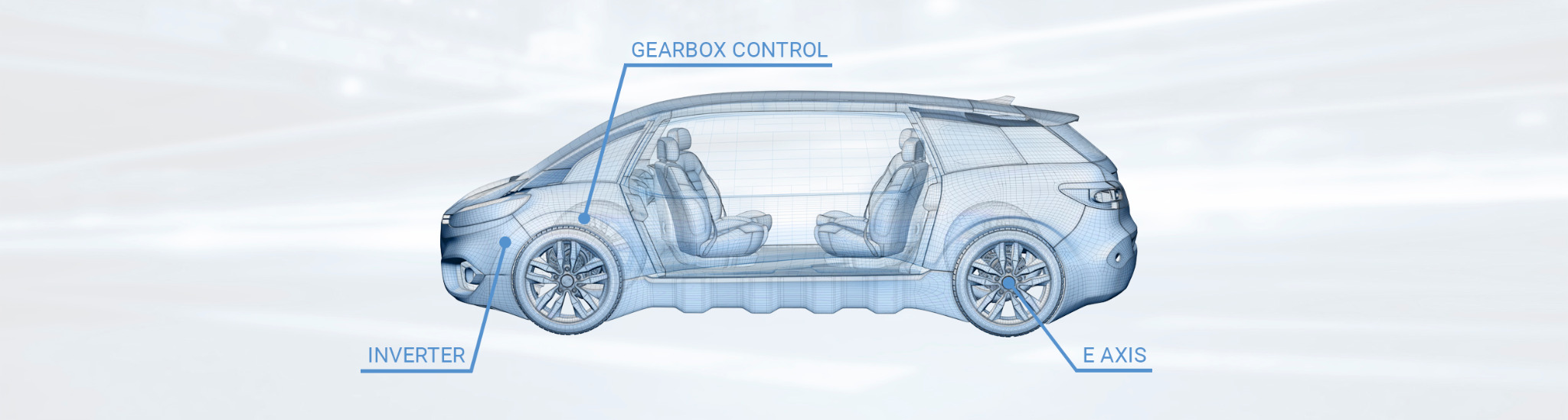

e-mobility

One off the core topics in the automation of manufacturing processes at Baumann is electromobility. Baumann Automation has been providing battery assembly systems for many years and specialises in automation solutions with networked production and control processes. Effective battery storage systems are needed to make the transition to electromobility a success.

battery

Baumann has a profound level of know-how and comprehensive knowledge in battery assembly systems – including modules, as well as complex storage systems such as pack assemblies. The company has far-reaching expertise in manufacturing highly complex systems through various national and international projects. Baumann builds production systems for energy storage for customers in the automotive industry.

Module assembly

In module assembly, the individual cells are wired in series and therefore connected with one another. As a result, module assembly provides various options for customers.

Battery assembly

Multiple modules and additional electronic elements (such as cables and control units) are combined when assembling the pack, which can then be installed into an electric vehicle.

End-of-line testing

End-of-line testing involves checking the product’s complete functionality. All relevant conditions are simulated and the reactions of the test specimen are recorded.

With its wide performance selection, Baumann can meet customer requirements flexibly and individually, while providing tailored solutions for the assembly of modules and packs.

Cell handling

Baumann guaranties a high quality standard and compliance with all legal framework conditions, such as safety measures (fire safety, PPE and emergency concepts) for cell handling. Customers are supported by trained personnel who have been instructed by EuP and AuS (live-line working) and offer workflow solutions. Prototype production phases can also be offered at Baumann where there is sufficient logistics and production space for this purpose.

Battery modul

In battery module assembly, the individual cells are wired in series and therefore connected with one another. The module assembly provides various options for customers such as: stacking, riveting, welding, screwing, dispensing, testing, cell handling, terminal welding, AGV integration, EOL testing, labelling/packaging, seal testing, module and battery handling as well as manual assembly without AuS (live-line working) aspects.

Battery pack

For pack assembly, Baumann provides an ideal solution for assembling complex complete units. Multiple modules and additional electronic elements (such as cables and control units) are combined when assembling the pack, which can then be installed into an electric vehicle. Baumann has multiple flexible assembly concepts for pack assembly in a combination of manual work stations and robot cells. The assembly concepts are scalable and can therefore be adapted to the ramp-up in production. This provides advantages for customers as they have a better investment to market.