SUSTAINABILITY AND INTEGRATED MANAGEMENT

Respect for nature, environmental responsibility and holistically integrated management – our commitment to a sustainable future

For mechanical engineering companies such as Baumann, resource consumption is determined more by infrastructure than production processes. The most important resources used in terms of quantity are gas, electricity, water and fuel. We attach great importance to sustainability and see it as our responsibility to make a positive contribution to protecting the environment and to champion the sustainable use of resources.

To this end, we are working hard to optimise all of our processes and are continuously searching for more environmentally friendly alternatives.

Quality

Quality

management

Quality management

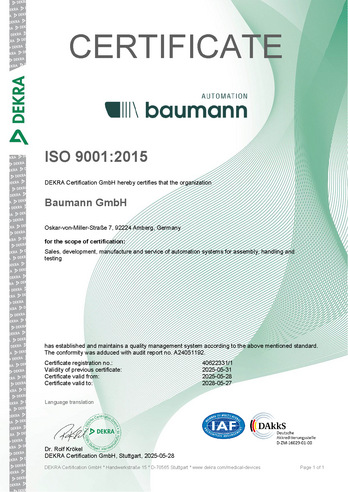

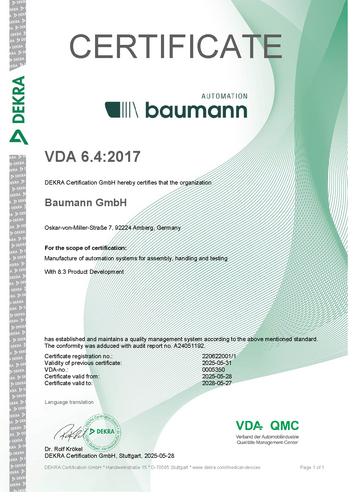

Continuous optimisation of quality management is part of how we guarantee the success of Baumann solutions. This is why Baumann GmbH is certified with the international management standard EN ISO 9001:2015 and VDA 6.4:2017 (Quality).

IM

policy

IM policy

Optimising customer satisfaction is one of our primary company principles. Our customers set the benchmark for quality. This means that our customers’ opinion of our quality is decisive.

With regard to our environmental and energy activities, we aim for sustainable improvements to environmental impacts in order to both preserve a liveable environment and to protect the energy and resources required for operating processes.

Each individual employee’s work plays a part in upholding our quality, environmental, information security and energy standards. It is therefore important to inform, train and motivate employees so that they have the necessary knowledge and skills to contribute to the company’s success.

We also ensure that quality, environmental, information security and energy-related activities are always planned, managed and monitored. This process-oriented approach is supported by all levels of management.

In this way, we ensure compliance with legal and official requirements as well as customer requirements in the form of specifications, policies, laws or other regulations.

With our continuous improvement process and results-oriented actions, the commitment of all our employees at all levels should steadily increase the quality of our products and protect environmental and energy resources.

This is supported by risk-based thinking, which involves always considering risks and opportunities.

Our IM policy is applied universally, discussed regularly and reviewed for continued adequacy.

Energy

management

Energy management

Sustainable business also means using resources responsibly. Improved working conditions and saving energy and materials also result in greater cost efficiency. This is why Baumann GmbH is certified with the international management standard EN ISO 50001:2018 (Energy).

Environmental

management

Environmental management

Our commitment to environmentally friendly business practices and efficient environmental management are key components of the Baumann philosophy. This is why Baumann GmbH is certified with the international management standard EN ISO 14001:2015 (Environment).

ESG

Compliance

Compliance

Our compliance system is of central importance, as it ensures that laws are not violated and that codes of conduct and internal company guidelines are always complied with. The system is regularly evaluated in order to ensure that it remains both effective and relevant, so that adjustments can be made if necessary.

Substainability

Substainability

As a modern, sustainable company, we are actively committed to caring for the environment and using comprehensive, integrated management methods.

We firmly believe that protecting the environment is not just an obligation – it can also inspire innovation and growth. We will continue to set benchmarks and regularly broaden our range of measures. In doing so, we not only offer our customers high-quality products and services, but also make a positive contribution to preserving our environment and society.

Our sustainability concept meets the highest standards and is reflected in our end product as well as throughout our entire corporate culture. Quality is both a promise to our customers and the keystone of our work.

Our sustainability report plays a core part in making our approach transparent and tangible. The report summarises our goals, the measures we are taking and our successes in fostering environmentally friendly practices within our company. It serves as an expression of our commitment and conveys to our customers and partners that we are invested in an ecological future.

Baumann has a presence on several renowned sustainability platforms, where we publish our activities relating to environmental and sustainability issues and ensure that these are documented.

Examples of this include:

This shows that we not only strive for economic success, but also take our responsibility towards the environment and society seriously.

Operational energy concept

To investigate energy supply and consumption, Baumann GmbH commissioned the Institut für Energietechnik IfE GmbH at OTH Amberg-Weiden (Amburg-Weiden Technical University of Applied Sciences) to create an energy concept.

As part of this operational energy concept, a comprehensive energy review was carried out, covering the thermal energy and electricity supply as well as CO2 emissions. The energy needs were assessed on the basis of the captured and recorded energy consumption data and coordination discussions.

This included considering the electricity supply and grid connection points, machine cooling and the required thermal energy.

The various energy supply scenarios were then developed on the basis of the needs assessment and their profitability was examined as part of a full cost assessment using the annuity method, which is based on VDI 2067. The total annual costs were then derived from this. In order to ensure comparability, all scenarios were determined using the same conditions.

A total of four energy supply scenarios were determined. All of the pellet and cogeneration scenarios have higher total annual costs than the reference scenario with natural gas boilers. All of the scenarios achieve a significant reduction in CO2 emissions compared to the reference scenario.

Various development scenarios were considered in assessing the increasing energy needs, and the combination of renewable energies (solar and wind) and the energy supply scenarios were also examined in terms of cost efficiency.

30% of the energy concept creation project was funded by the Bavarian State Ministry of Economic Affairs, Regional Development and Energy.