Enhanced flexibility for EOL testing of power converters

12. Aug 2020

With the baumann power|box, Baumann Automation provides you with a flexible platform for test engineering applications.

The baumann power|box supports you when testing assemblies and control units, reliably meeting the requirements for quality assurance and a zero-defect strategy in production.

The modular design offers a compact, space-saving and optimally accessible testing system. Quick retooling and the ability to change from a stand-alone system to an integrated part of a production line also reduces investment costs and allows you to gradually expand your production.

Modular design for flexibility

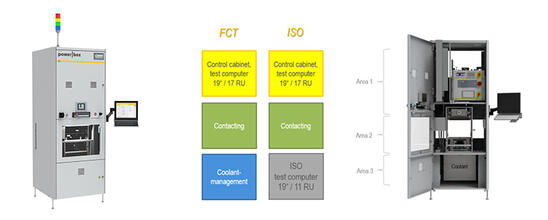

The modular design of the power|box

comprises of a control cabinet, 19-inch test computer, mechanical test unit

and temperature control unit. There are

multiple loading options:

- Manual loading directly into the component holder, using a drawer or with a rotary table

- Automatic loading with a conveyor belt inside or outside the power|box, with a robot

Due to the often long testing times, multiple power|box systems can be directly integrated into a fully automatic production line. This way, it is possible to combine power|box systems for various testing tasks, e.g. functionality and isolation tests with a baumann flex|box.

The control units are fed into the system using a workpiece carrier transport system. Loading an individual power|box is carried out using a robot. This allows the system to be adapted to production at any time, saving time and space.

Due to the modular design and multiple loading options, the power|box provides excellent adaptation capabilities for production.

Löhnert Elektronik testing technology and software

Löhnert Elektronik performance testing technology is designed for functional and ISO testing according to your specific test specifications.

The integrated testing technology is consistently built up in modular 19-inch technology and provides unique advantages:

- Use of qualified functional modules

- Reduction of the planning work through large existing function blocks

- Flexible construction of new projects or changes to existing projects

- Better serviceability through replacement and external repair

The test sequence is programmed either using the Löhnert test and

automation software LisRT with Python as the sequencer language or using

TestStand.

The test sequence is programmed according to your test specifications and you can adapt it yourself with the integrated development environment. The device drivers are collected for each project according to the hardware configuration. LisRT contains the infrastructure for test facilities, from type-dependent limit value specification to customer-specific measurement data transmission to an MES system.