Virtual commissioning and simulation

18. Nov 2022

Baumann Automation has been involved in the simulation and virtual commissioning of robots and complete plants for years.

The aim is to support the development of plants and their software as early as possible in order to avoid problems or expensive changes in later project phases. Anticipatory and solution-oriented elaboration ensures the best possible cycle time.

The advantages of the simulation solution are, in addition to fast tests of robot reachability and programme sequences, that all common controllers can be connected and programmed.

With the help of a specially developed optimisation workflow, important system parameters are automatically optimised.

In addition, Baumann Automation is working intensively on research projects to integrate predictive maintenance into the plants.

Application scenarios

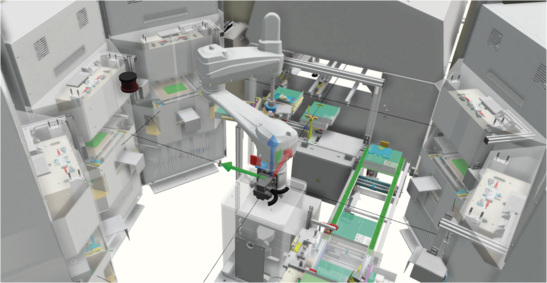

Robot simulation

Through detailed simulation of the motion sequences, the robot can be optimally adjusted to the plant - even automatically with the Baumann optimisation system.

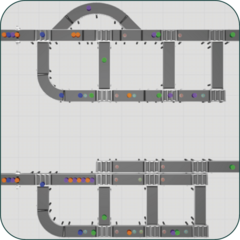

Materialflusssimulation

Material flow simulation

The analysis of the plant logistics is an important part of the planning; here, congestion situations or flow-inhibiting components can be identified and solutions can be developed.

Virtual commissioning

Commissioning times are shortened by parallelising the programming. Since no access to the plant is necessary, changes and updates can also be reliably tested without interrupting production.